A

Air gap

An ‘air gap’ is non-magnetic material, which is present between a magnet and an attracted object or between two magnets that are attracting each other.

An air gap is best described as a break in the magnetic circuit, which magnetism has to jump through to continue a circuit between north and south poles. The introduction of an air gap weakens the magnetic hold.

An air gap can be air itself or a solid non-ferrous material that does not conduct magnetism such as wood, plastic or aluminium. It could also be a thickness of paint or a surface that is very uneven. Refer to the ‘Pull-gap’ curve entry for a description of how pull strength decreases as the size of an air gap increases.

Anisotropic

A magnet is described as anisotropic if all of it’s magnetic domains are aligned in the same direction. This is achieved during the manufacturing process and ensures that the domains are 100% orientated in the same direction to deliver maximum magnetic output. This direction is called the ‘magnetic axis’.

The alignment is achieved by subjecting each magnet to a strong electromagnetic field at a critical point during the manufacturing process, which then ‘locks’ the domains parallel to the applied electromagnetic field.

An anisotropic magnet can only be magnetised in the direction (along its magnetic axis) set during manufacture, attempts to magnetise the magnet in any other direction will result in no magnetism. Anisotropic magnets are much stronger than isotropic magnets, which have randomly orientated magnetic domains producing much less magnetism. However, isotropic magnets have the advantage of being able to be magnetised in any direction.

Axially magnetised

The term axially magnetised describes a magnet that is magnetised between two flat parallel surfaces.

B

- Bar magnet

- A bar magnet is exactly as it sounds, it is a permanent magnet which has a magnetic length which is greater than its diameter or effective diameter for rectangular bar magnets. A bar magnet has a north and a south pole typically at opposite ends of the bar

- B-H curve (magnetic flux density-magnetic field curve)

-

Sometimes referred to as the ‘magnetisation curve’ or ‘demagnetisation curve’, the B-H curve is a graphical representation showing the relationship between ‘magnetic flux density’ (B) and the ‘magnetic field strength’ (H) required to demagnetise a specific magnet. This graph is the second quadrant of a four quadrant hysteresis curve.

The magnetic flux density increases in proportion to the field strength until it reaches a point of saturation and becomes constant even as the field strength continues to increase.

Magnetic flux density is measured in Gauss (G) or Tesla T, where 10,000 Gauss equals 1 Tesla. Magnetic field strength is measured in Oersteds (Oe). When analysing anisotropic materials if the magnetic field is not applied in parallel or perpendicular to the objects anisotropy axis then the measurements of the B-H curve are not valid.

C

- Closed circuit

- A closed magnetic circuit describes an arrangement of magnetic and ferrous material which directly connects the north pole of a magnet to the south. In a closed circuit the lines of magnetic flux are allowed to flow freely from north to south and all of the magnetic flux density is retained within the closed circuit. In a closed circuit, there is no external magnetic field as all the magnetism is consumed in the circuit.

- Coercivity

- The coercivity of a magnetic field is the intensity, or energy, required to reduce the magnetisation of a magnetised (to the point of saturation) object to zero. Essentially, it measures a magnetic material’s resistance to demagnetisation. The coercivity of magnetic material is measured in Oersteds (Oe) – the higher the number, the greater the magnet’s resistance to demagnetisation.

- Curie temperature

-

The properties of all magnetic materials change when they are heated to a particular temperature. The Curie temperature (Tc), or Curie point, is the temperature at which the atomic structure of magnetic material is changed and the object becomes demagnetised.

Once heated to, or passed, the Curie point the magnetic domains of the material are released and become randomised and ‘self keepering’, resulting in permanent magnetic damage. As a result, the magnet will not emit any external magnetic fields.

D

- Demagnetisation

-

Demagnetisation occurs when a magnet loses its external magnetic field when in open circuit.

This can be through physical stress or corrosion, through heating the magnet beyond its maximum operating temperature or by exposing the material to a strong demagnetising magnetic field.

Generally, neodymium magnets cannot be re-magnetised once their magnetic properties have been lost.

- Density

-

Density is a measurement of a materials mass per unit of volume. All materials have different densities and a magnet’s density can allow you to calculate its weight. The density values for the different types of magnetic material are as follows:

- Neodymium magnets have a density of up to 7.5g per cm3

- The density of alnico magnets vary depending on the grade from 6.9 to 7.3g per cm3

- The density of samarium cobalt magnets vary depending on the grade from 8.2 to 8.4g per cm3

- Ferrite magnets have a density of 5g per cm3

- Flexible magnets have a density of 3.5g per cm3

- Diamagnetic

- Diamagnetism is a kind of magnetism that aligns itself at right-angles to the direction of an objects magnetic field and therefore has a repellent force. All materials are diamagnetic to a certain degree but only when exposed to an externally applied magnetic field. The effect is generally weak in most materials, and is completely overpowered in materials that display other magnetic characteristics. However, the effects of diamagnetism can be enhanced by introducing superconductors into the magnetic circuit.

- Diameter

- Diameter applies to magnets that are round in shape and is the measurement taken from one side of a flat round surface to the other cutting directly through the exact centre of the object. Diameter is twice the radius of the magnet.

- Diametrically magnetised magnets

- Cylindrical magnets are described as diametrically magnetised when their direction of magnetism is parallel to the diameter of the magnet, rather than perpendicular to the flat faces of the cylinder.

- Dimensional tolerance

-

Magnets are produced in batches and during the machining operations, the tolerance dictates the maximum and minimum permissible size.

Neodymium magnets tend to have a standard tolerance of +/-0.1mm, although +/- 0.05mm can be achieved.

- Dimensions

- The finished size of a magnet, including all surface treatments such as coatings and platings.

- Direction of magnetisation

- Magnets can be specified and ordered to be magnetised across any axis, allowing them to be used to different effect. The direction of magnetism determines which side of the magnet the north and south poles appear. This has to be specified before manufacture as, for example, an anisotropic rectangular magnet can only be magnetised in one of the three possible directions.

- Domains

-

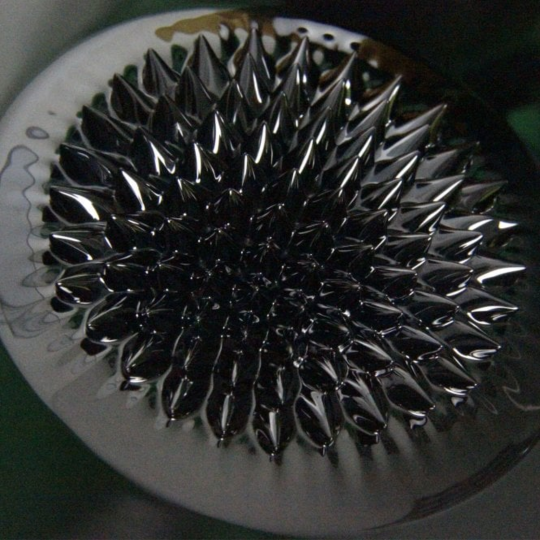

Magnetic materials such as permanent magnets are split into individual microscopic domains. The magnetic domain structure of a material is responsible for its magnetic characteristics such as those displayed by metallic elements and alloys like permanent magnets.

Each domain is a region which has a uniform direction of magnetisation, however, different domains may have different directions of magnetisation. During the process of manufacturing magnetic material, electromagnets align each domain, providing the greatest magnetic energy and giving the finished material anisotropy.

E

- Electromagnet

-

Unlike permanent magnets, the magnetic field exerted by an electromagnet is produced by the flow of electric current. The magnetic field disappears when the current is turned off.

Typically, an electromagnet consists of many turns of copper wire which form a solenoid

When a DC electric current flows around the solenoid coil, a magnetic field is created. If an iron core is inserted into the bore of this solenoid, then magnetism is induced into it and it becomes magnetic, but immediately becomes nonmagnetic when the current stops flowing.

F

- Ferromagnetism

- Ferromagnetism is the strongest form of magnetism and is the only form that creates forces so strong that they can be noticed by human hands. A ferromagnetic substance is strongly attracted by a magnet.

- Flux

- Magnetic flux is the number of lines of magnetism travelling from a magnetic pole. The CGS unit of measurement for ‘flux’ is Maxwells and the SI unit is Webers.

- Flux density

-

Flux density describes the number of lines of magnetism in each square centimetre of pole area.

The total number of magnetic field lines penetrating each 1cm x 1cm pole area is called the magnetic flux density (also known as magnetic induction). Flux density is measured in Gauss, or Tesla (10,000 Gauss = 1 Tesla).

G

- Gauss

-

Named after the famous German mathematician and physicist Carl Friedrich Gauss, the Gauss is a unit of measurement for magnetic flux density.

1,000 Gauss is 1,000 lines of magnetism in each cm2 of pole area.

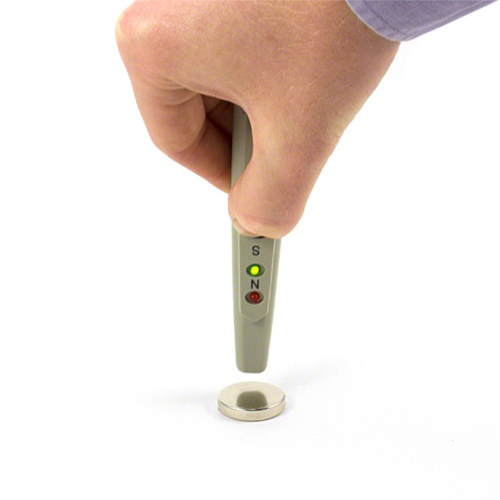

- Gauss meter

- A gauss meter is used to measure the flux density (Gauss) of a magnet. A gauss meter has a hall probe, which when placed onto a magnetic pole will display the number of lines of magnetism within each cm2 of pole area.

- Grade

-

There are a number of different types of magnet, neodymium, samarium cobalt, ferrite and alnico, for example.

Each type of magnet is manufactured in a number of different grades. The term grade defines the chemical characteristics of the material and its magnetic properties. Each grade of material, depending upon its core elements and how it is manufactured will have different magnetic properties.

You will find a list of magnet grades right here in our Tech Centre.

- Gilbert

- The Gilbert (G) is a unit to quantify magnetomotive force named after William Gilbert who was an English scientist and physician born in 1544 and is credited by many as being the father of electricity and magnetism. An alternative measure for magnetomotive force is ampere-turns (At); the Gilbert (G) is a slightly smaller unit than ampere-turns. To convert from ampere-turns to Gilberts multiply by 1.25664.

H

- Homogeneous field

- An homogenous magnetic field is one where the lines of the magnetic field are uniform, creating an equal force/current in all places within the field. Homogenous fields are difficult to achieve with permanent magnets.

- Horseshoe magnet

- The most recognisable style of magnet, a horseshoe magnet is a permanent magnet, usually made from alnico material. In most cases a horseshoe magnet will have a north pole on one of its tips and the south pole on the other. Horseshoe magnets are typically stronger than bar magnets as their pull is doubled when attached to a piece of ferrous material that spans both its poles, therefore creating a closed circuit.

- Hysteresis loop

-

A four quadrant graph, showing magnetising force relative to resultant magnetisation of a permanent magnet material as it is successively magnetised to its saturation point, then demagnetised, magnetised in the reverse polar direction and then finally re-magnetised.

When the cycles are complete, this four quadrant graph will be a closed loop which illustrates the magnetic characteristics of the magnetic material under test. Magnetically hard materials have a larger area inside the loop which denotes the level of magnetic energy. Magnetically soft materials lose magnetism when the magnetising field is removed and therefore these have very small areas inside the loop. The second quadrant within the four quadrants (+X and -Y) is the most important of the four curves and is known as the demagnetisation curve.

![]()

- High field gradient magnet

- High field gradient magnets have the highest clamping forces in direct contact with ferrous material, but the weakest pull through larger air gaps.

I

- ID (inner diameter)

-

The acronym ‘ID’ refers to the measurement of the inner diameter of a magnet. For example, for a ring magnet, the inner diameter would be the measurement of the diameter of the centre hole.

![]()

- Induction, (B)

-

Magnetic induction, also known as flux density is the number of lines of magnetism in each square centimetre of pole area.

The total number of magnetic field lines penetrating each 1cm x 1cm pole area is called the magnetic flux density (also known as magnetic induction). Flux density is measured in Gauss, or Tesla (10,000 Gauss = 1 Tesla).

- Intrinsic coercivity (Hci)

-

If the coercivity of a magnet is the force required to cancel out a saturated magnet’s magnetic field, the intrinsic coercivity is the force required to permanently demagnetise a magnet. Neodymium magnets have large differences between the coercivity and intrinsic coercivity, therefore to permanently demagnetise a neodymium magnet takes much more energy than to just equalise (reduce to zero) a neodymium magnet’s magnetic field. Intrinsic coercivity is measured in kilo-Oersteds (kOe).

Each grade of neodymium magnet has an associated intrinsic coercive force, displayed on the ‘neodymium magnet grades’ page of our Tech Centre.

- Irreversible losses

- Partial demagnetisation can be caused by exposure to high temperatures, external magnetic fields, shock or vibration. When exposed to certain conditions a magnet will regain any magnetism lost, however, in extreme situations the magnet will lose a percentage of its magnetism that won’t be recovered, known as irreversible losses. An example is exposing a magnet to temperatures exceeding its maximum operating temperature.

- Isotropic

- A magnet made of magnetically isotropic material has no preferred direction of magnetism and has the same properties along either axis. During manufacture, isotropic material can be manipulated so that the magnetic field is applied in any direction. Neodymium magnets are anisotropic due to their strength, on the other hand, flexible magnets are usually isotropic allowing all of the magnetic field to be exerted from one side of the sheet.

K

- Keeper

- A keeper is a steel bar or disc placed between and attached to opposite poles of a magnet to allow all the magnetism to flow from one pole to the other. The keepered magnet will appear completely non-magnetic until the keeper is removed. Keepers were needed for old alnico magnets to preserve magnetism in these low coercivity magnets. This is useful if magnets need to be airfreighted and stray magnetism needs to be contained. Neodymium, samarium cobalt and ferrite magnets do not need to be keepered to protect their magnetism, however they are sometimes keepered to make them safer to handle.

M

- Magnetic axis

- In an anisotropic magnet, all of the magnets magnetic domains are aligned to face the same way. The line of direction that the domains follow is called the magnetic axis. An anisotropic magnet can only ever be magnetised along its magnetic axis.

- Magnetic circuit

-

All magnetism flows from north to south and a magnetic circuit is the journey that it takes to get from north to south.

Magnetism is usually generated by permanent or electromagnets and passes through magnetic paths within the circuit. The circuit may also include one or more ‘air gaps’ filled with non-magnetic material. Magnetic circuits are used in devices such as motors, generators and transformers as an efficient method of channelling magnetic fields.

- Magnetic domain

-

Magnetic materials such as permanent magnets are split into individual microscopic domains. The magnetic domain structure of a material is responsible for its magnetic characteristics such as those displayed by metallic elements and alloys like permanent magnets.

Each domain is a region which has a uniform direction of magnetisation, however, different domains may have different directions of magnetisation. During the process of manufacturing magnetic material, electromagnets align each domain, providing the greatest magnetic energy and giving the finished material anisotropy.

- Magnetic field strength (H-field)

- Magnetic field strength is the measure of a magnetising field originating from an electrical current or a permanent magnet. Magnetic field strength is measured in Oersteds (Oe).

- Magnetic induction (B-field)

-

Magnetic induction, also known as flux density is the number of lines of magnetism in each square centimetre of pole area.

The total number of magnetic field lines penetrating each 1cm x 1cm pole area is called the magnetic flux density (also known as magnetic induction). Flux density is measured in Gauss, or Tesla (10,000 Gauss = 1 Tesla).

- Magnetic length

- Magnetic length refers to the dimension of a magnet which follows the direction of a magnet’s magnetic axis. A magnet’s magnetic length is always listed last when referring to a magnet’s physical dimensions. For example, a bar magnet magnetised along its length might be described as 50mm x 50mm x 100mm

- Magnetisation (M)

- Magnetisation refers to an object producing a magnetic field.

- Magnetised

- A material, or magnet is defined as magnetised when it exerts a magnetic field, either because of its interaction with an electromagnet or another permanent magnet.

- Magnetomotive force (mmf)

- Magnetomotive force is the magnetic field produced by a coil of wire when current is passed through it. The more current that is passed through a solenoid coil and the more coils the solenoid has, the larger the magnetic field produced. A magnetomotive force is expressed in ampere-turns; a value of the amount of applied current multiplied by the number of turns in a solenoid. Alternatively magnetomotive force is sometimes measured in Gilberts.

- Material

-

The term material refers to the physical composition of a magnet. For example, neodymium magnets are made out of a neodymium alloy (NdFeB) material containing neodymium (Nd), iron (Fe) and boron (B).

There are five main types of magnetic material and they are:

- Neodymium

- Alnico

- Ferrite

- Samarium Cobalt

- Flexible magnets

- Maximum energy product (BHmax)

-

The maximum energy product of a magnet is measured in ‘Mega-Gauss Oersteds’ (MGOe). Known as the maximum energy product value, this is the primary indicator of a magnet’s ‘strength’. In general, the higher the maximum energy product value, the greater the magnetic field the magnet will generate in a particular application. In neodymium grading, the two numbers in a grade name (e.g. N42) represent the maximum energy product for that grade. The higher the value, the greater the magnetic field strength the magnet will exert in a particular application and the smaller the volume of magnet required.

(BH)max is a product of remanence (Br) and coercivity (Hc) and represents the area under the graph of the second quadrant hysteresis loop.

Each grade of neodymium magnet has an associated maximum energy product, displayed on the ‘neodymium magnet grades’ page of the Tech Centre.

- Maximum Operating Temperature (Tmax)

-

The maximum operating temperature is exactly as it sounds, it represents the maximum temperature that a particular grade of magnet will be able to function at, before it becomes permanently demagnetised.

All permanent magnets weaken in relation to their temperature coefficient, but as long as the maximum operating temperature is not exceeded, this is fully recoverable on cooling. If the maximum operating temperature is exceeded, then the losses will not be fully recovered on cooling. Repeatedly heating a magnet above its maximum operating temperature and cooling will significantly demagnetise the magnet.

Neodymium magnets operate best in cold temperatures down to approximately -130oC. Regular neodymium magnets will maintain their magnetism in operating temperatures up to 80oC whereas different variants of neodymium magnets can operate up to temperatures of 230 oC.

The maximum operating temperature for each grade of magnet material is displayed on the ‘How does temperature affect neodymium magnets’ page of the Tech Centre.

- Maxwell

- Maxwell is a measurement for magnetic flux on the CGS scale where 1 Maxwell is equal to 1 line of flux. The measurement is named after James Clerk Maxwell who was a Scottish theoretical physicist born in 1831. Maxwell’s most high-profile achievement was formulating a set of equations that united electricity, magnets and optics into one consistent theory. Maxwell’s achievements were widely acclaimed as the second great unification in physics after those realised by Isaac Newton.

- Mega Gauss Oersteds (MGOe)

-

Mega Gauss Oersteds is the CGS measure of the maximum energy product of a magnet (BHmax).

The five main types of magnet material have the following typical maximum energy products:

- Neodymium upto 52 MGOe

- Alnico upto 5.5 MGOe

- Ferrite up to 3.5 MGOe

- Samarium Cobalt up to 32 MGOe

- Flexible magnets up to 2 MGOe

- M-H loop (Hysteresis loop)

-

Also known as the hysteresis loop, the M-H loop is a four quadrant graph, showing magnetising force relative to resultant magnetisation of a permanent magnet material as it is successively magnetised to its saturation point, then demagnetised, magnetised in the reverse polar direction and then finally re-magnetised.

When the cycles are complete, this four quadrant graph will be a closed loop which illustrates the magnetic characteristics of the magnetic material under test. Magnetically ‘hard’ materials have a large area inside the loop which denotes the level of magnetic energy. Magnetically ‘soft’ materials lose magnetism when the magnetising field is removed and therefore these have very small areas inside the loop. The second quadrant within the four quadrants (+X and -Y) is the most important of the four curves and is known as the demagnetisation curve.

![]()

- Monopole

- Currently, the existence of magnetic monopoles remains theoretical as their existence has not yet been proven. In theory, every magnet must have a north and south pole and magnetism flows from one to the other. Without both poles there is no flow of magnetism.

N

- North pole

- The north pole of a magnet attracts to the earth’s geographic North Pole. As ‘like’ poles repel and ‘opposite’ poles attract, this means that the earth’s North Pole is actually a south pole (or a north seeking pole).

O

- Oersted

- The Oersted (Oe) is a measure for magnetic field strength and is named after the Danish physicist and chemist Hans Christian Oersted. In 1820, Oersted discovered the magnetic effect of electric current, contributing significantly to the study of magnetism. The Oersted is closely related to the Gauss measurement for flux density and is used to measure external electromagnetic forces usually produced in magnetisers and demagnetisers.

- Open circuit

- A magnet is said to be in open circuit when it is not attached to any other ferrous material, meaning that its lines of magnetic flux make their way from the north pole to the south pole through the air alone, rather than through a ferromagnetic material. Because it is more difficult for lines of magnetic flux to travel through air rather than other parts of a circuit, a magnet produces less Gauss when in open circuit.

- Orientation

- A magnet’s orientation refers to the physical location and direction of its magnetic poles, e.g. through length, thickness, diameter, axially ,radially or diametrically.

P

- Permeability

-

Some materials, when placed inside a magnetic field, become magnetised themselves. The permeability of a magnetic substance represents the increase or decrease of the magnetic field inside the substance compared to the magnetising field that the substance is located within. Simply put, it is the ability for a material to acquire its own magnetism or for magnetism to flow through it.

Ferromagnetic metals have the greatest permeability of all substances and will become magnetised when exposed to a magnetic field. The rate of magnetic permeability will increase until the substance reaches a point of saturation. ‘Soft’ ferromagnetic materials are easily magnetised, but once the external field is removed they lose most of their magnetism. Conversely, ‘hard’ ferromagnetic materials are difficult to magnetised, but once they are, they will remain magnetised.

- Permanent magnet

- A permanent magnet is a solid material that produces its own consistent magnetic field because the material is magnetised. A permanent magnet is different to an electromagnet as an electromagnet only acts as a magnet when an electric current passes through its coils.

- Plating

-

Plating is another term for coating. Platings or coatings are applied to raw neodymium magnets to prevent corrosion and demagnetisation. The most common coating is a layer of nickel, followed by a later of copper and then another layer of nickel.

At first4magents.com we can provide many different coatings and platings for bespoke applications, including:

- Rubber

- Nickel (Ni)

- Epoxy

- Zinc (Zn)

- Gold (Au)

- Tin (Sn)

- Titanium (Ti)

- Titanium Nitride (TiN)

- Parylene C

- Everlube

- Chrome

- Polytetrafluoroethylene (PTFE, also known as Teflon Ni-Cu-Ni plus Epoxy)

- Nickel-Copper-Nickel, plus Rubber

- Zinc, plus Rubber

- Nickel-Copper-Nickel, plus Parylene

- Nickel-Copper-Nickel, plus PTFE

- Tin, plus Parylene

- Zinc chromate

- Phosphate Passivation

- Polarity

- All magnets have both a north and a south pole, usually 180o apart. Polarity refers to a magnet’s magnetic orientation with regards to its poles. Opposite poles attract each other but similar poles repel.

- Pole

- The pole of a magnet is the area of a magnet which has the greatest magnetic field strength in a given direction. Each pole is either north facing or south facing.

- Pull-gap curve

-

A pull-gap curve plots the ‘pulling power’ of a magnet in direct contact with a thick and flat piece of steel and then though a steadily increasing range of air gaps. Pull follows an inverse square law relationship with distance.

High field gradient magnets have the highest clamping forces in direct contact with ferrous material (zero air gap), but the weakest pull through steadily increasing air gaps.

Low field gradient magnets have the lowest clamping forces in direct contact with ferrous material (zero air gap), but the highest pull through steadily increasing air gaps.

A high field gradient magnet’s pull-gap curve and a low field gradient magnet’s pull-gap curve will cross over if plotted on the same graph.

- Pull strength

- The pull strength is the highest possible holding power of a magnet, measured in kilograms. It is the force required to prise a magnet away from a flat surface of steel when the magnet and metals have full and direct surface-to-surface contact. The grade of the metal, surface condition and angle of pull all have an impact on the pull strength.

R

- Rare-earth metals

- Rare-earth metals are categorised in the periodic table in the group known as Lanthanides. The most common elements in this category are neodymium, samarium and dysprosium. Despite the name, rare-earth elements are relatively abundant in the earth’s crust, however, they are not typically found in economically exploitable deposits and are often dispersed, deriving the term ‘rare-earth.’

- Remanence (Br)

- Remanence is described as the magnetism that is left in a magnet, after the removal of the external magnetic force applied to magnetise it. When a material has been magnetised, it has remanence, as the magnetism has at some point been induced by an external magnetic field.

- Repelling

- When two magnets are placed close together with the same poles facing each other, e.g. north facing north or south facing south, they will always repel one another. The reason for this is because the magnetic fields being generated by each magnet are trying to flow in the same direction and when placed closed together they collide, having a repellent effect.

S

- Shear force / sliding resistance

-

As a rule of thumb it is five times easier to slide a magnet than to pull it vertically off the surface of a ferrous material.

When a magnet slides on steel, the coefficient of friction is approximately 0.2 and this is how the five times is derived.

Magnets attached to a vertical steel wall will slide down the wall when only 20% of the rated pull is experienced as a load. Rubber coated magnets have a much higher coefficient of friction and therefore will resist sliding at a far higher rate because of the friction caused by the coating.

If the vertical wall is made of thin sheet steel which cannot absorb all the magnetism generated by the magnet, then the holding force will be reduced further.

- Single domain particle

- A particle that is so small there is no room for a magnetic domain wall. Hence the particle is a tiny but very strong magnet. All magnetic recording tapes are made using such particles.

- South pole

- In magnetic terms this is the specific pole of the magnet which ‘seeks’ the earths geographic South Pole. The earth’s geographic South Pole actually has a magnetic north polarity, thus greatly confusing the issue.

- Stacking

- Stacking refers to the process of placing magnets together to increase the net pull strength . When five magnets are stacked together to make one magnet which is five times thicker, then this magnet will be substantially more powerful because of the increase in its L/d ratio (length to diameter). Once the length of the magnet exceeds the diameter of the magnet, the magnet is working at an optimum level and further additions to magnetic length will provide only small increases in performance.

- Surface Field / surface gauss

- The surface field strength is measured in Gauss and is the magnet’s maximum field strength taken from the magnet’s pole surface. Measurements are usually taken using a gauss meter.

T

- Temperature coefficient (T)

- Temperature coefficient is a factor that is used to calculate the decrease in magnetic flux corresponding to an increase in operating temperature. The loss in magnetic flux is recovered when the operating temperature is decreased, providing the maximum operating temperature is not exceeded. The temperature coefficient for magnetic materials are typically;

-

- Neodymium 0.11 % per degree C rise in temperature

- Alnico 0.02% per degree C rise in temperature

- Ferrite 0.2% per degree C rise in temperature

- Samarium cobalt 0.03 % per degree C rise in temperature

- Flexible magnets 0.2 % per degree C rise in temperature

- Tesla (T)

- The Tesla is a unit of measurement for magnetic flux density. It is named after Nikola Tesla who was a Serbian-American inventor, engineer and physicist. One Tesla is equal to 10,000 Gauss.

- Thread

- Some magnets are manufactured to include a thread for fixing in their applications. Neodymium magnets themselves are generally not threaded as they are too brittle, instead a neodymium magnet will be fixed to or encased within another material which will be threaded.

W

- Weight

- Weight refers to the weight of one single magnet made of magnetic material.