Neodymium Magnets - Coatings and adhesives

COATINGS

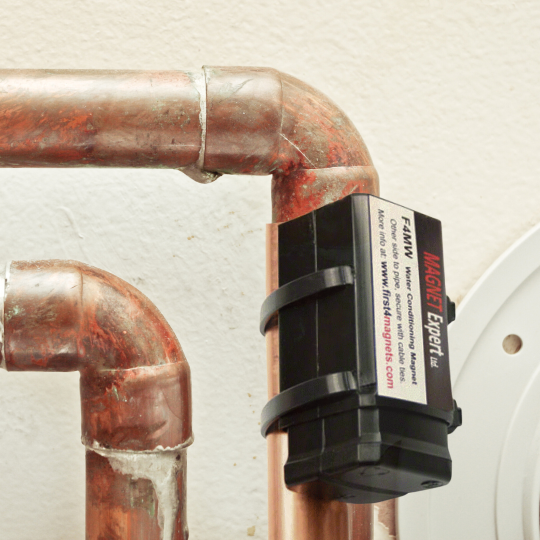

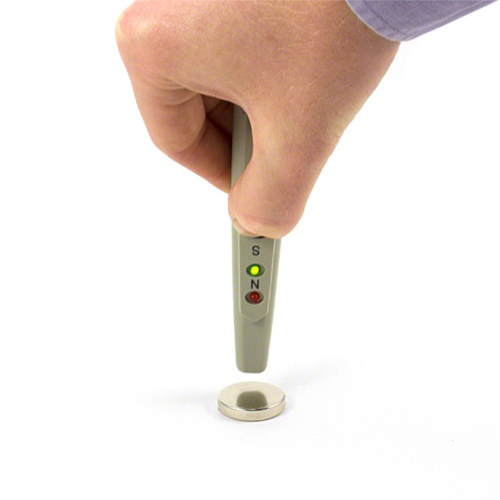

Neodymium magnets are very hard, but very brittle. Plus, as neodymium magnets also contain iron it means they are prone to corrosion if they aren’t coated. They are so prone to corrosion that even the moisture in the atmosphere can cause an uncoated neodymium magnet to corrode over time. If a magnet corrodes it will weaken and crumble. That’s why, at first4magnets.com we supply all our magnets already triple-coated (unless specifically requested otherwise). The typical coating for a neodymium magnet is a layer of nickel followed by a layer of copper and then nickel again. However there are many different coatings used with neodymium magnets including gold, rubber and Polytetrafluoroethylene (PTFE). The coating applied to a raw neodymium magnet depends on the application it will be used for, potential coatings include:

- Nickel-Copper-Nickel (Ni-Cu-Ni)

- Rubber

- Nickel (Ni)

- Epoxy

- Zinc (Zn)

- Gold (Au)

- Tin (Sn)

- Titanium (Ti)

- Titanium Nitride (TiN)

- Parylene C

- Everlube

- Chrome

- Polytetrafluoroethylene (PTFE)

- Nickel-Copper-Nickel, plus Rubber

- Zinc, plus Rubber

- Nickel-Copper-Nickel, plus Parylene

- Nickel-Copper-Nickel, plus PTFE

- Tin, plus Parylene

- Zinc chromate

- Phosphate passivation

During manufacture, all our magnets are thoroughly dried to prevent moisture being captured underneath the coating during the coating and plating process. A neodymium magnet kept in dry conditions - not subjected to excessive heat, radiation or strong external magnetic fields - will not corrode and will retain its magnetic output for many, many years. Permanent magnets [link to: permanent magnets in technical terms section] lose their magnetism at a rate of approximately 5% every 100 years, meaning they aren’t actually ‘permanent’ in the truest sense of the word but handled with care, in the right conditions neodymium magnets will maintain their magnetism for a very long time.

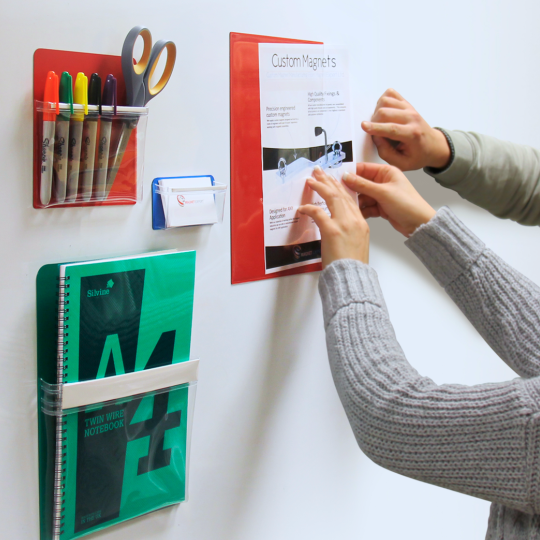

ADHESIVES

With the right adhesive, magnetic and non-magnetic material can be bonded to other surfaces. Clean and grease free services provide best bonding surface. At first4magnets.com we recommend the following adhesives for use with our neodymium magnets.

- Araldite Rapid Adhesive

- Loctite Industrial Strength Adhesive

How to buy Neodymium Magnets