Shop By Material

At FIRST4MAGNETS® we supply magnets and magnetic assemblies in a range of materials. The main types of magnetic material are Neodymium, Flexible rubber, Ferrite, Alnico, and Samarium Cobalt. Each type of magnet has different magnetic properties and each magnet is available in different grades.

If you are unsure about which magnet to choose give our technicians a call; they are experts in all types of permanent magnets so whatever your application they will be able to help you find the ideal magnet.

NEODYMIUM MAGNETS

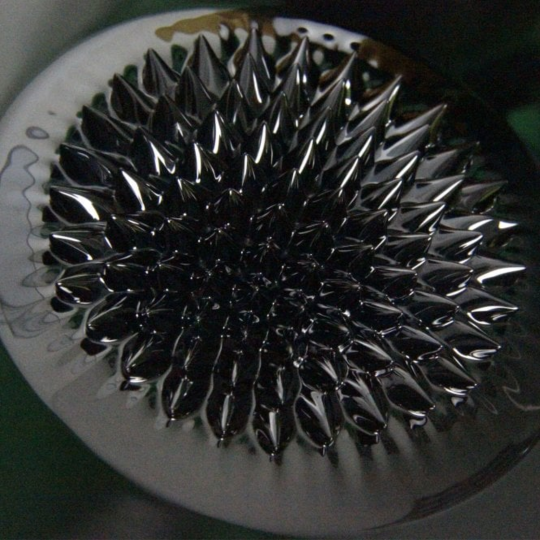

Neodymium magnets are a type of rare earth permanent magnet and the strongest magnets available. Our neodymium magnets are available in 15 different shapes and over 100 size combinations; you won’t find a wider range anywhere else.

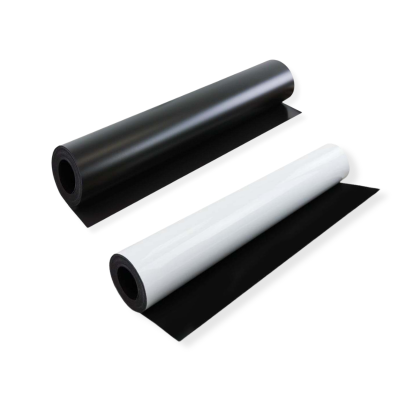

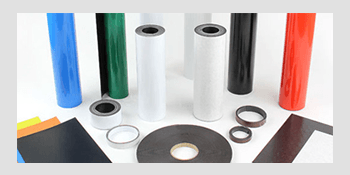

FLEXIBLE MAGNETS

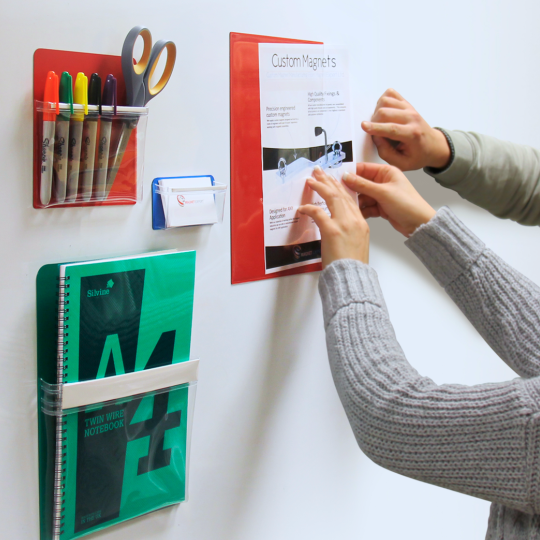

Flexible magnets are made from premium raw materials and are manufactured by combining ferrous particles with a polymer binder to create a magnetic rubber. In our flexible range, you will find a wide selection of shapes and sizes including magnetic tapes, sheets, and labels available in a variety of colours and finishes. Flexible magnets are used for unique applications that would not be possible to be using other 'hard' magnets.

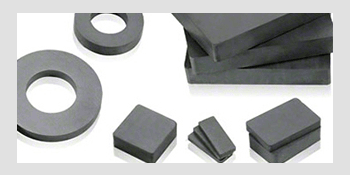

FERRITE MAGNETS

Ferrite magnets are not as strong as other permanent magnets but they offer excellent value for money. They are reasonably resistant to corrosion and can operate in temperatures up to 180°C. Larger ferrite magnets generate a deep magnetic field and are commonly used as clamping magnets or in magnetic conveyor systems. They have a high resistance to heat and corrosion which makes them most popular in everyday applications.

ALNICO MAGNETS

Alnico magnets are made from a material consisting of aluminium, nickel, and cobalt. The first true permanent magnet to be developed, they are perfect for high temperature applications and have a high resistance to corrosion, however, they are susceptible to being demagnetised. Alnico magnets are commonly manufactured in traditional horseshoe and bar shapes. Alnico magnets are commonly used to teach children about magnetism.

SAMARIUM MAGNETS

Samarium cobalt magnets are another type of rare earth magnet developed before neodymium magnets. Samarium cobalt magnets are not as powerful as neodymium magnets but they have superior resistance to corrosion and can withstand operating temperatures up to 300°C. This makes them suitable for working in high temperature environments and applications. Samarium cobalt magnets are available in a wide variety of shapes and sizes.

LEARN MORE ABOUT MAGNETS

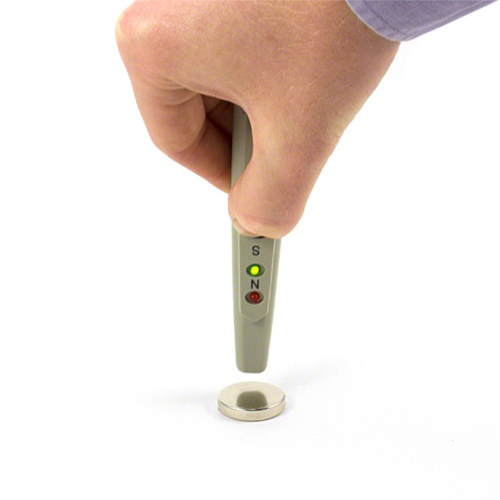

Each type of permanent magnet has its strengths and weaknesses. When choosing the perfect magnet we always start with understanding the application before selecting the suitable magnet. While it is important to choose the right magnet material, shape, size, coating and type of assembly are all equally as important.

All permanent magnets work best when they have a direct and flush surface to surface contact with mild steel of equal thickness or another magnet. Below are a few key considerations:

Attracting or Clamping

If you are looking to attract a ferrous object over a distance then you require a raw magnet, ideally made from neodymium. Neodymium magnets produce the largest magnetic fields and are therefore the best for attracting objects over a greater distance. The ideal shape and size of the magnet depend very much on the application.

If you are looking for the maximum clamping force against a steel surface, for example suspending something in a vertical or shear position then you require a pot or clamping magnet.

Both of these assemblies consist of a magnet with a steel shell which concentrates the magnetism on one face and increases friction for maximum clamping force. Pot and channel assemblies typically use neodymium or Ferrite magnets.

Operating Temperature

For applications that generate high temperatures samarium cobalt and Alnico magnets are an obvious choice as they have the highest maximum operating temperatures of all permanent magnets.

However, although regular grades of neodymium magnets have low maximum operating temperatures (80°C) they can be produced in special high-temperature grades with much higher maximum operating temperatures. All of our high temperature magnets are marked with a red thermometer icon.

Environment

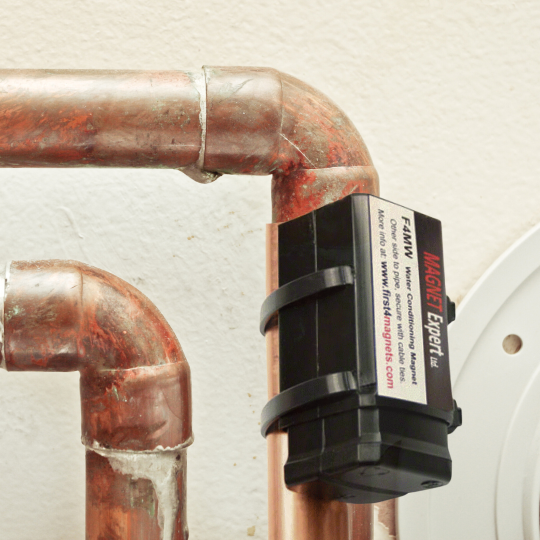

For outdoor applications or applications used in demanding environments, it is important to consider the corrosion resistance of the material. Ferrite magnets, Alnico magnets, and samarium cobalt magnets all have high resistance to corrosion without any protective coating.

Neodymium magnets are highly susceptible to corrosion but can be supplied with one of many different coatings. Our neodymium magnets are typically coated with a triple layer of nickel, copper, and nickel but can be supplied with many other coatings including but not limited to rubber, epoxy, gold, and PTFE.