All magnets have a ‘pull’ rating measured in kilograms which relates to how much force acting perpendicular to the magnet to pull the magnet from a steel plate, when in direct contact.

The ‘pull’ rating is obtained and calculated under ideal conditions such as a thick enough steel plate which is perfectly flat and clean. As the pull force is slowly steadily increased and is absolutely perpendicular to the magnet face.

However, in real world applications, perfect conditions are unlikely and there are six main factors which could affect and reduce the performance of the magnet.

Steel Thickness – Absorption of magnetism

If a magnet needs the contact steel to be 10mm thick to absorb all the magnetism and deliver maximum pull, then attracting the magnet to a 1mm thick sheet steel surface will result in 90% of the magnetism being wasted and the actual pull delivering only 10% of its maximum capability.

To get the best performance out of your magnet its key to ensure the magnet is attracting and no stray magnetism is leaving the steel.

One way to test that no magnetism is lost is to apply a second steel plate behind the contact steel in which your magnet is attracted to, if this small plate remains attracted then the magnetism is not being fully absorbed by the contact steel, meaning it is too thin.

Alternatively, if the small steel plate falls away from behind the contact steel, then the steel is absorbing all magnetism meaning the steel is thick enough.

Another factor to note is that applying thicker steel can not increase the ‘pull’ rating of a magnet.

.

.

Air Gaps – Affect magnetic circuit

Air gaps are another factor which can reduce the performance of a magnet. An air gap refers to any non-magnetic material that prevents magnetism from attracting to another magnet or ferrous object.

Air gaps can be formed if the contact steel is rusty, dirty, painted or uneven, and these will all cause a loss of magnetism.

Air gaps affect the magnetic circuit that a magnet produces, breaking these circuits and subsequently forcing the magnetism to ‘jump’ from the magnet to the other object to continue the circuit.

The bigger the air gap, the bigger the reduction in the magnets performance and pull.

Material – Determines ability to conduct magnetism

The material in which the magnet is attracting to will affect its performance, as they are tested on a mild steel, which are preferred to alloy steels and cast irons as its ability to conduct magnetism is much higher.

Alloy steels and cast irons have a reduced ability to conduct magnetism which therefore reduces the pull of a magnet, limiting its ability. Cast iron can reduce the pull strength of a magnet by up to 40% due to the fact it’s a less permeable than mild steel.

Other materials such as copper and zinc are not magnetic and are commonly used as coating for magnets.

Sheer Force – Determines performance

Magnets can be fixed within a sheer or vertical position dependant on the application. When magnets are fixed in a vertical position this is known as the sheer position.

It’s five times easier to slide a magnet rather than to pull it away when separating it from the surface its attracting to. This is due to the coefficient of friction which is typically 0.2 for steel-on-steel surfaces.

When using a magnet in a sheer position it’s important to note that if it has a pull strength of 10kg, it will be able to support 2kg. If an object being held by a magnet is heavier than the magnets sheer position pull power, then the magnet will begin to slide down the surface.

Temperature – Maximum operating temperature

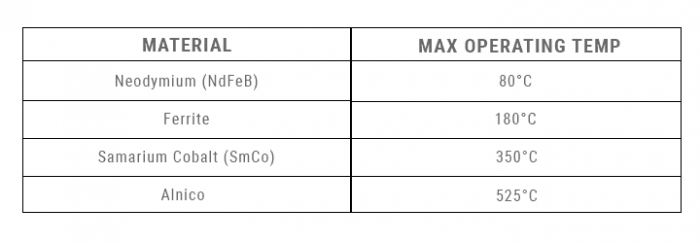

Subjecting a magnet to temperatures above its maximum operating temperature will cause it to lose performance, which won’t be recovered with cooling. If the process is repeated it will result in a significant decrease in performance from the magnet.

Exposing a magnet to temperatures above the maximum operating temperature causes the magnetic domains to become miss-aligned, causing a reduction in magnetism.

If magnets are continuously exposed to heat above their maximum operating temperature, they will become permanently demagnetised.

In contrast if a magnet is continuously exposed to low temperatures, its strength may even increase due to its magnetic properties being enhanced.

However, some magnets are designed to maintain performance under extreme heats such as Samarium Cobalt, Ferrite and Alnico and are commonly used within high temperature applications.

.

.

.

Corrosion – Exposure to water

Magnets are commonly use within outdoor applications, which leaves them exposed to harsh weather and conditions. For example, exposure to water can affect the performance and pull of a magnet.

If the plating of a magnet becomes damaged, the magnet is more prone to water exposure. This exposure could lead to rust, resulting in deterioration in magnetic performance.

Certain magnets including Samarium Cobalt and Ferrite magnets are designed to maintain performance in harsh conditions and are both resistant to corrosion.