Neodymium magnets are technological marvels and the process for creating them is sophisticated and delicate.

The main ingredients of a neodymium magnet are neodymium itself, iron, and boron; the chemical compound known as NdFeb. The exact ingredients depend on the grade or strength of magnet being produced.

However, the production process for different strength magnets sees the same size different stages required to produce a neodymium magnet.

.

Step 1 – The Mix

Firstly, all the elements to make the chosen grade of magnet are placed into a vacuum induction furnace, heated and melted to form the alloy material.

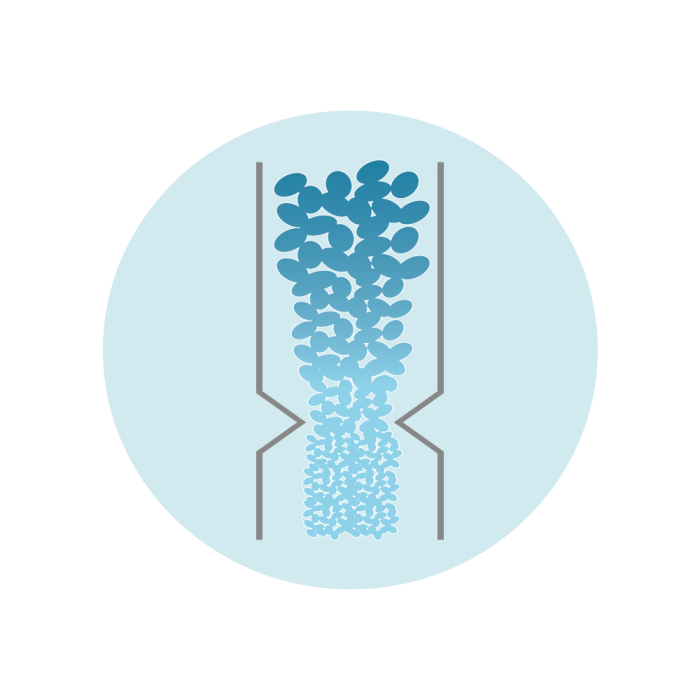

This mixture is then cooled to form ingots before being ground into tiny grains in a jet mill. Each grain is typically only three microns in size, smaller than a red blood cell.

.

Step 2 – Pressed

The super-fine powder is then pressed in a mould and at the same time magnetic energy is applied to the mould.

The magnetism comes from a coil of wire that acts like a magnet when electrical current is passed through it.

As the mixture is pressed, the direction of magnetism is locked in! When the particle structure of the magnet matches the direction of magnetism, this is called an anisotropic magnet.

Step 3 – Sintered

This isn’t the end of the process, instead, at this point the magnetised material is demagnetised and will be re-magnetised later in the process.

At this stage the material would be far too soft and crumbly to be useful.

The next step is for the material to be heated, almost until melting point in a process called sintering which makes the powdered magnet particles fuse together.

This process takes place in an oxygen free, inert environment.

.

Step 4 – Cooled & Machined

Almost there, the heated material gets rapidly cooled using a technique known as quenching.

This rapid cooling process minimises areas of poor magnetism and maximises performance.

This is the stage when the raw magnets are machined into their desired shape, however, because they are so hard diamond plated cutting tools are needed!

.

Step 5 – A coat for all applications

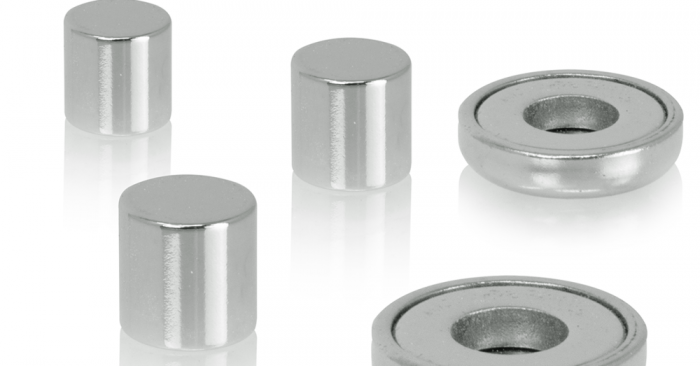

The last step before the material is re-magnetised is vital. Because neodymium magnets are so hard, making them prone to breaking and chipping, they must be coated, cleaned, dried and plated.

There are many different types of coating that are used with neodymium magnets, the most common being a nickel-copper-nickel mixture but they can be coated in other metals and even rubber or PTFE.

.

Step 6 – Magnetised

Once plated, the finished material is re-magnetised by placing it inside a coil, which, when electric current is passed through it produces a magnetic field three times stronger than the required strength of the magnet.

This is such a powerful process that if the magnet is not held in place it can be flung from the coil like a bullet.

Finally, every magnet sold by FIRST4MAGNETS is quality assured before it is dispatched to the customer to be used in hundreds of different applications.

If you have any questions or queries then be sure to get in touch with our team of experts who are available on 0845 519 4701 or sales@magnetexpert.com and are always happy to help.