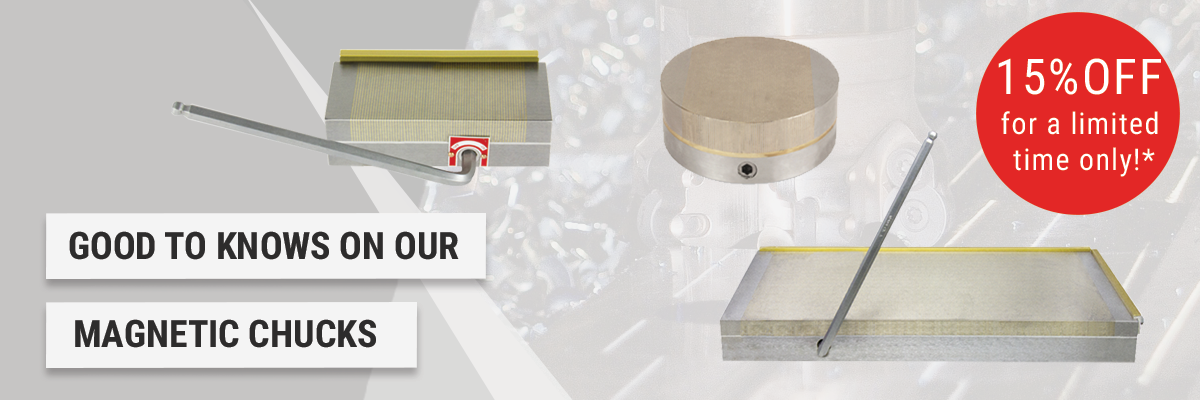

*15% off our magnetic chucks! Offer ends on 19/10/2020!

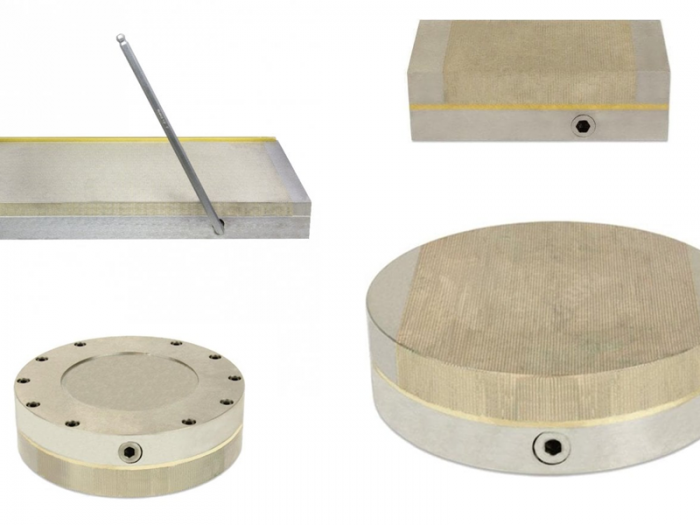

Standard Pole Magnetic Chucks

- Shapes available: Rectangular & Circular

- Rectangular Sizes: 160mm x 70mm x 45mm to 600mm dia x 300mm x 58mm

- Circular Sizes: 125mm dia x 48mm to 500mm dia x 65mm

- Material: Neodymium

- Removable operating handle provides simple on-off switching.

- Suitable for thicker workpieces from 3mm and above.

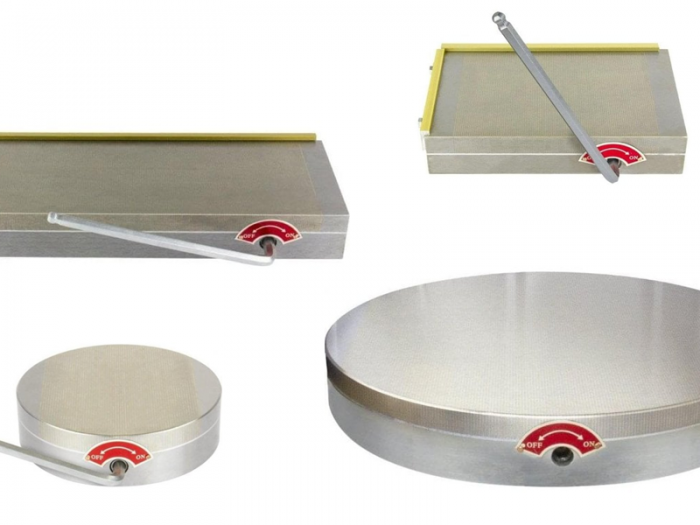

Fine Pole Magnetic Chucks

- Shapes available: Rectangular & Circular

- Rectangular Sides: 160mm x 70mm x 45mm to 600mm dia x 300mm x 58mm

- Circular Sides: 125mm dia x 48mm to 500mm dia x 65mm

- Material: Neodymium

- Removable operating handle provides simple on-off switching.

- Suitable for workpieces from 0.7mm to 3mm.

Top tip

You can magnetically clamp a fine pole pitch on top of the standard pole, so you can machine thinner steal and without having to remove the standard chuck.

Common Applications

Magnetic Chucks are an alternative to the traditional workholding machinery, as they use magnetic force from permanent magnets to clamp and secure work pieces in place. Our magnetic chucks have been engineered to give the customer an effective and instant holding force, that will consistently and safely clamp the material they are working on. Magnetic chucks give users higher rates of productivity when grinding, cutting and milling ferrous metals, as demonstrated below:

Frequently Asked Questions

How Do They Work?

A magnetic chuck is activated by manually turning the key from on to off position. Within the chuck, the magnets are always active, however the magnetic flux remains locked inside the chuck when it is turned off.

Once the chuck is turned on, the magnets are aligned with the top plate, and the magnetic flux travels above the top plate. When a work piece is applied to the top, it is secured as the flux is locked on to this. This will allow the user to securely work on the work piece.

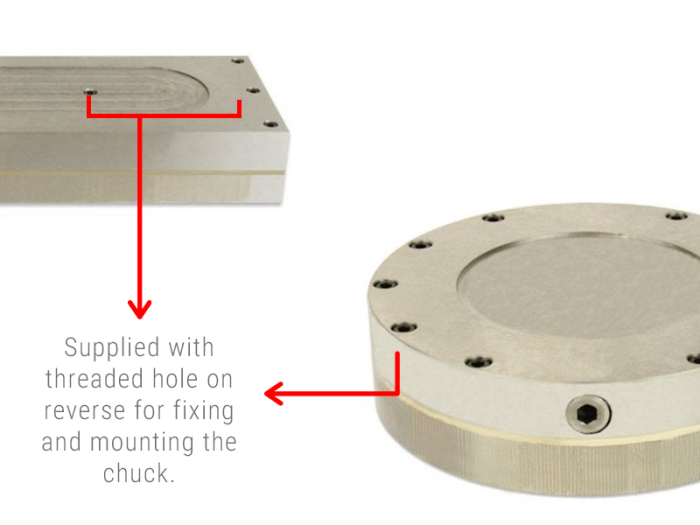

How do I attach them to my work bench?

Simply screw the chuck to your work bench using the mounting points on the base of the magnetic chuck.

Top tip

Using chucks for milling or grinding etc, can cause bits of ferrous materials to shatter on the floor. Have you seen our magnetic sweepers? They are perfect for collecting up all metal swarf that is dropped onto the floor when the metal has been machined.