Alnico magnets have now been manufactured for over 100 years, in which time the process has not drastically changed.

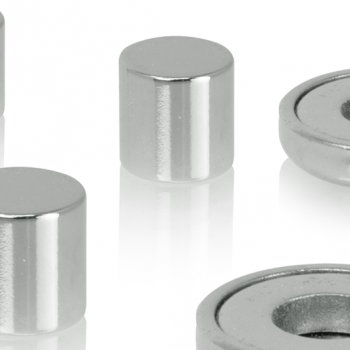

Alnico magnets are permanent magnets that are primarily made up of a combination of aluminium, nickel and cobalt but can also include copper, iron and titanium.

In this blog we will be explaining the manufacturing process of Sintered Alnico magnets, smaller Alnico magnets, weighing grams rather than kilograms are usually created using the sintering process.

Sintering is generally the process used when a high volume of magnets are required.

.

.

Step 1 – Milling

Before sintered Alnico magnets can be produced the raw elements must first be finely ground by milling into tiny particles.

The powdered magnetic material is then pressed under tonnes of pressure in a die, which closely resembles the magnets desired shape.

.

.

Step 2 – Sintering

Once the powder has been pressed, the material is sintered in a furnace in a hydrogen atmosphere at over 1200oC.

This process fuses all the pressed particles together to form one magnet.

.

Step 3 – Cooling

The red hot material is then cooled. At this point if the material is cooled in the presence of an external magnetic field then it will have anisotropic properties and a preferred magnetic direction, making it stronger.

If an external magnetic field is not applied then the magnet produced will be isotropic without a preferential direction of magnetism.

.

Step 4 – Pressed

Generally sintered Alnico magnets do not require further shaping or machining as the die they are pressed in is made to be very close to the desired shape of the magnet.

If a specific coating is required, this is done right at the end of the process, just before the magnets are finally magnetised.

The poles of the magnets may be fettled to leave them bright and shiny.

.

.

Step 5 – Magnetising

Finally the raw magnetic material is magnetised by placing it inside a coil or solenoid magnetiser and in one fifth of a second, the electrical pulse generates the necessary field needed to fully magnetise the magnets.

We stock a small range of red epoxy painted high quality Alnico magnets in a range of different shapes and sizes.

Every magnet sold by FIRST4MAGNETS is quality assured before it is dispatched to the customer to be used in hundreds of different applications.

If you have any questions or queries then be sure to get in touch with our team of experts who are available on 0845 519 4701 or sales@magnetexpert.com and are always happy to help.